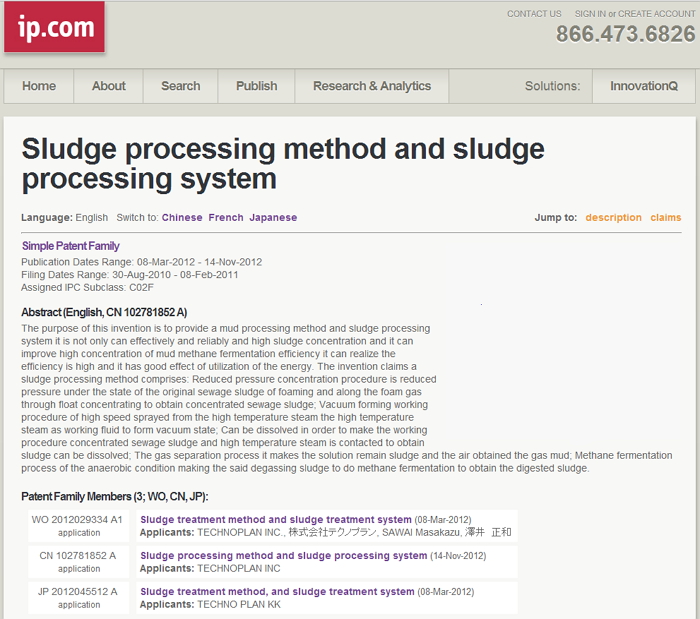

WO 2012029334 A1

application

Sludge treatment method and sludge treatment system (08-Mar-2012)

Applicants: TECHNOPLAN INC., 株式会社テクノプラン, SAWAI Masakazu, 澤井 正和

CN 102781852 A

application

Sludge processing method and sludge processing system (14-Nov-2012)

Applicants: TECHNOPLAN INC

JP 2012045512 A

application

Sludge treatment method, and sludge treatment system (08-Mar-2012)

Applicants: TECHNO PLAN KK

Abstract (English, CN 102781852 A)

The purpose of this invention is to provide a mud processing method and sludge processing system it is not only can effectively and reliably and high sludge concentration and it can improve high concentration of mud methane fermentation efficiency it can realize the efficiency is high and it has good effect of utilization of the energy. The invention claims a sludge processing method comprises: Reduced pressure concentration procedure is reduced pressure under the state of the original sewage sludge of foaming and along the foam gas through float concentrating to obtain concentrated sewage sludge; Vacuum forming working procedure of high speed sprayed from the high temperature steam the high temperature steam as working fluid to form vacuum state; Can be dissolved in order to make the working procedure concentrated sewage sludge and high temperature steam is contacted to obtain sludge can be dissolved; The gas separation process it makes the solution remain sludge and the air obtained the gas mud; Methane fermentation process of the anaerobic condition making the said degassing sludge to do methane fermentation to obtain the digested sludge.

Claims (English, CN 102781852 A)Jump to: description top

1 sludge processing method includes: Decompressing and concentrating sequence the decompression state of the original sewage sludge foaming well as the foam gas through float concentration so as to obtain concentrated sewage sludge; Vacuum forming sequence in high speed sprayed from the high temperature steam and the high temperature steam as working fluid to thereby form vacuum state; Can be dissolved in order to make the working procedure concentrated sewage sludge and high temperature steam contact so as to obtain sludge can be dissolved; The gas separating sequence making said solution sludge can be retained and the air so as to obtain the gas mud; Methane fermentation sequence in the anaerobic condition of the said degassing sludge to do methane fermentation so as to obtain digested sludge.

2 according to claim formula of said sludge processing method wherein the dry used through the said methane fermentation sequence obtained by the digested sludge as raw sludge.

3 sludge processing system comprises: Decompressing and concentrating device and the decompression state of the original sewage sludge foaming well as the foam gas through float concentration so as to obtain concentrated sewage sludge; High temperature steam spraying device the high speed sprayed from the high temperature steam; Ejector using the same the high temperature steam as working fluid to form vacuum state; Can be dissolved groove which makes said concentrated sewage sludge and high temperature steam contact so as to obtain sludge can be dissolved; The gas separating groove which makes said solution sludge can be retained and the air so as to obtain the gas mud; Methane fermentation tank the anaerobic condition making the said degassing sludge to do methane fermentation so as to obtain digested sludge.

4 according to claim the sludge processing system wherein the dry it by using said methane fermentation tank to get the digested sludge as raw sludge.

- For more details of this patent, please click here to visit ip.com