Produce liquefied Activated Carbon from Sewerage Sludge

New patent pending technologies allow to produce bio liquefied activated carbon which is a highly demanded environment cleaning agent from sewerage sludge. In addition, the technologies require no gas, no chemical, no large facility and no unwelcome odor.

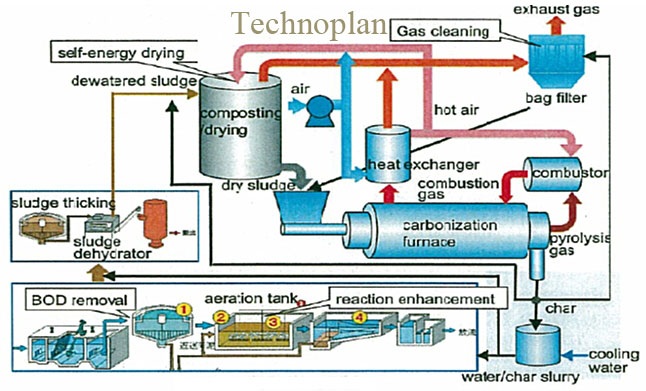

Sewerage Sludge To produce bio activated carbon, How?

With this system, you can produce the bio activated carbon for 1 ton a day from 10 tons of the sewage sludge (80{659260bfee9de372d251cf0f46d0d196324d619c8a7170325fda8dcf2b881e37} moisture content).

Which means the compost will turn to be the world welcome bio activated carbon, which can be water treatment agent, deodorant, sludge reduction agent, or others.

You may produce high quality high-performance liquid adsorbents from bio activated carbon, which help water treatment a lot.

The common global problem of today is?

Currently, most of wet biomass, such as sewage sludge and food waste, is burnt and transport by human power to the places far from residential area in order to avoid unwelcome odor when they get decomposed.

However, such incineration treatment requires a desulfurizing agent for fossil fuels and exhaust gas treatment,which has a lot of problems globally.

The main emissions sources are wastes and sludge

The main emissions sources are wastes, sludge and so on, and the suppression of emissions from these sources and improvement in the process of handling these materials are under consideration to reduce the emissions of the gas.

Can we use it as fertilizer like old days?

On the other hand, as the traditional solution for the wet biomass, it can be recycled as compost as a fertilizer for farm lands. However, this traditional method also have some serious real life problem such as heavy metal inclusions in the fertilizer, unwelcome odor from the compost plant.

Summary of our technologies

You can produce high performance liquid cleaning agents from the compost which is from wet biomass.

Therefore,

- You don’t have to use fossil fuels to manufacture activated carbon and compost from wet biomass.

- You can eliminate the acid gas from carbonization furnace, and unwelcome odor from the compost reduction.

- Bio liquid activated carbon is an advanced liquid cleaning agent environment , which will save a lot of cost of the productions.

Summary – from the reports made to the Japanese government

- Our composting device has the capability of well functioned wet biomass fermentation.

- It can also work as solar energized dehydrator utilizing the vent effect to maintain aerobic.

- Therefore, you may consider that the compost product is also a valuable energy.

- If you use this compost created energy, you are able to manufacture carbon without the use of fossil fuels.

- The carbon produced from the compost will have high adsorption performance by the microorganism effects.

- This special high performance carbon can absorb the ammonia generated in the composting and the sulfurous acid gas generated in the canonizations.

- As a result, the special carbon can generate the ammonium sulfate is a fertilizer component.

- Therefore, you can have the system for deodorization and desulfurization for exhaust gas treatment, that require no chemicals at all.

How you can use bio liquefied activated carbon?

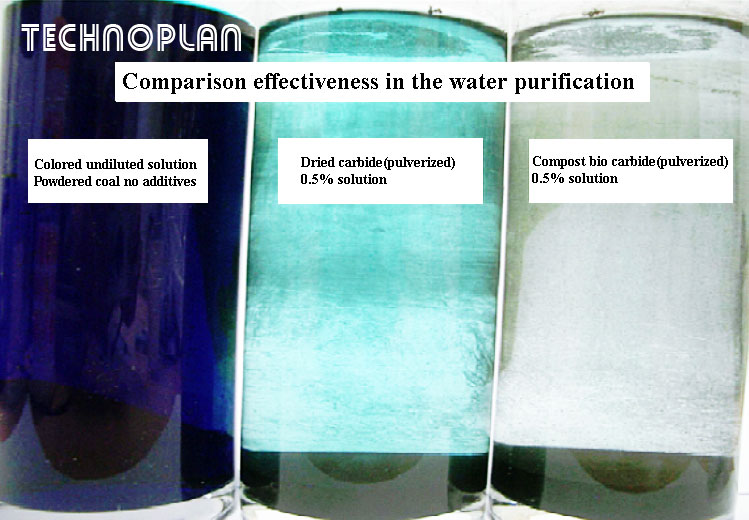

Our bio liquefied activated carbon is made from the compost pulverized up to 50 micron and added with water. By pulverizing the carbon to such micro level, the activated surface can be increased up to 100 times. Also, by mixing with water, it increases flocculation adsorption by capillary effect and the surface activity of the liquid phase.

This bio liquefied activated carbon can be utilized to save costs.

- Using it during the first precipitation step of water treatment, it can improve the recovery rate of raw solid.

- Using it during water treatment processing, COD removal rate can be improved to reduce the load of water treatment.

- Using it during sludge treatment process, it eliminates unwelcome odor of the sludge.

If you use our bio liquefied activated carbon system, it let you save a lot of money. Based on rough calculations, the new bio carbon will give you approx. USD1,000 /ton.

Imagine, the wasted sewerage sludge becomes useful resources.

In the past, the wet biomass such as sewage sludge and food waste, have been only as the subject of processing fee. They were really just “waste”. We can change it. The clean energy such as wind energy is fine. But you still spend a lot of energy to throw away your everyday sewerage sludge. Imagine, the wasted sewerage sludge becomes useful resources. If your every flush in your toilet turns to be money. Multiple problems will be solved by this one solution. This is the system for future.

- Wastewater treatment center can save a lot of process costs

- Wastewater treatment center can act as a factory for the highly demanded bio liquefied activated carbon

- Wastewater treatment center can be earth friendly bio fertilizer producer which will leads to be more organic farmers as bio fertilizer will be easier to get

What are you waiting for?

Our Inventions in the world news

US Fed News Service, Including US State News ; February 20, 2012

US Fed News Service, Including US State News ; December 1, 2012

US Fed News Service, Including US State News ; March 11, 2012

US Fed News Service, Including US State News ; September 15, 2011

Dehydration and transportation system for sludge

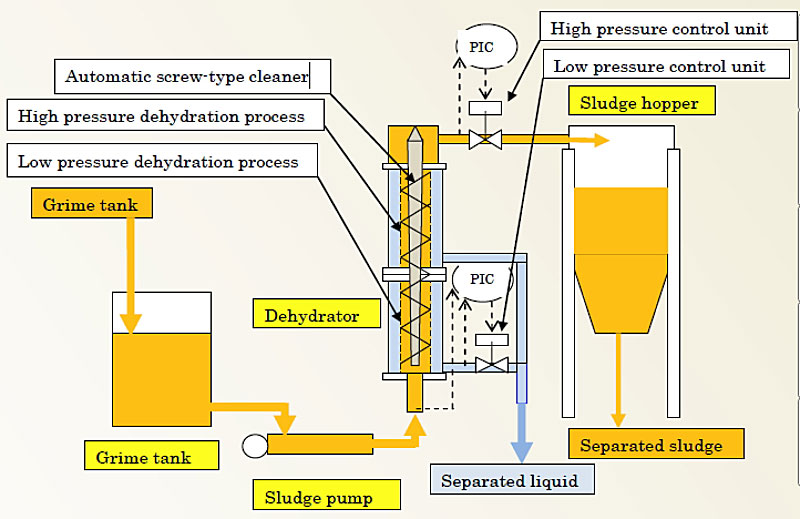

This system can dehydrate and transport sludge by only the power of the pump.

This system can perform dehydration and transportation of sludge with only one pump. Offensive odors do not leak outside of the device, because dehydration and transportation of the sludge happens in an airtight container. Facilities and maintenance costs are very low because this system can run automatically all day.

The problems of today’s sludge treatment and dehydration processing

- High cost of processing equipments

- High cost of maintenances

- Relatively larger building is required for the processing

Our system solved all.

Our system requires no separated transport system, no separated deodorization device or building.

Also, you may dehydrate and transport sludge by using only the power of the pump.

The filtration is cleaned automatically by a rotary screw driven by transportation of sludge.

The sludge is filtered at low pressure first, and at high pressure next. Dehydration is promoted efficiently with two different pressure phases. Dehydrated sludge can be transported without a conveyor and does not need a deodorization device.

[weaver_youtube http://youtu.be/pH__JAL00Tk sd=0 percent=70 ratio=.5625 center=1 rel=0 https=0 privacy=0]

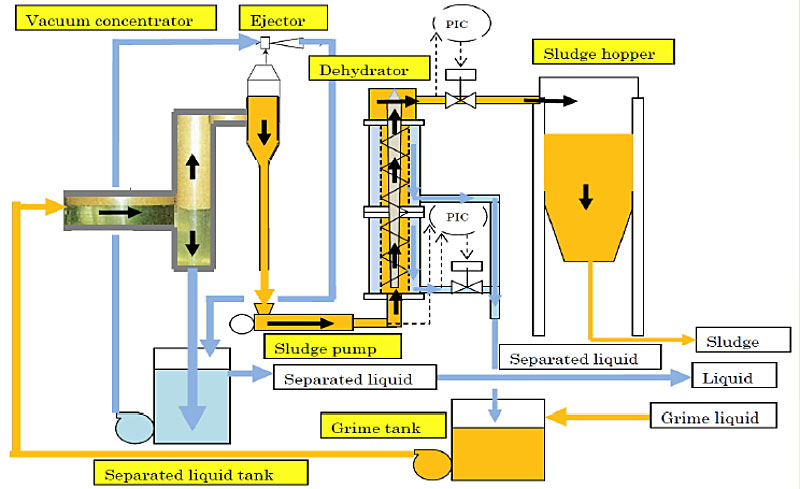

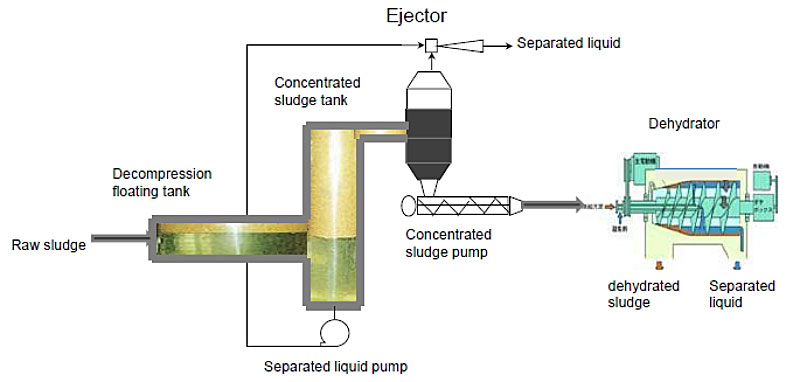

When sludge density is light ,the vacuum concentration system functions effectively. The vacuum concentration technology is incorporated in a system shown in the chart below.

Why you should use our system?

The dehydration speed increases, because the density of sludge increases. The dehydrator filtration liquid becomes light density by supplying it to a vacuum concentrator. Dissolution gas of the sludge is degassed in a vacuum concentrator, decreasing any unpleasant odors.

Summery

- Our technology makes it possible to produce organic sludge by everyday sewage treatment easily.

- The construction costs for such a faculty can be low as this system requires no costly heavy conveyor systems and its building.

- Further more, it requires no separated deodorization facilities which allows the system to be perfectly sealed structure.

- The operations costs as well as facility maintenance costs are relatively very lower than current ordinal systems as this system can be run continuously without human operator.

Sludge Vacuum Concentration and Volume Reduction System

Dissolved gas is degassed from sludge under a vacuum to float and concentrate the sludge and reduce the sludge volume.

This invention makes it possible to:

- Degas the gas dissolved in sludge under a vacuum to float,

- Concentrate the sludge,

- Flocculate the sludge without using a coagulant

at the same time.

Frequent Problems: large power source and facilities for re-dehydration process required

When the concentration of sludge has been 1{659260bfee9de372d251cf0f46d0d196324d619c8a7170325fda8dcf2b881e37} or less, the dehydration processing of the sludge becomes more difficult.

Therefore, the volume reduction in activated sludge generated by the treatment of sewage and food factory drainage is in troubles often. Thus, as a pre-dehydration process, pressure floating concentration technology has been used.

For the work, Some large power source and facilities required, such as air compressors and stirrersare, a flocculation reaction tank where coagulant is added to flocculate the sludgenecessary for dehydration and volume reduction of the sludge by water treatment.

[weaver_youtube http://youtu.be/XV-Z0AgEMew sd=0 percent=70 ratio=.5625 center=1 rel=0 https=0 privacy=0]

This new technology helps to resolve:

No need for a sludge concentration facility that requires a large power source and a large installation area

No need for a flocculation reaction tank that requires a stirring power source and a coagulant.

Other than pumps for supernatant liquid and sludge, there is no moving parts. You can build a low cost, simple and easy run facility.

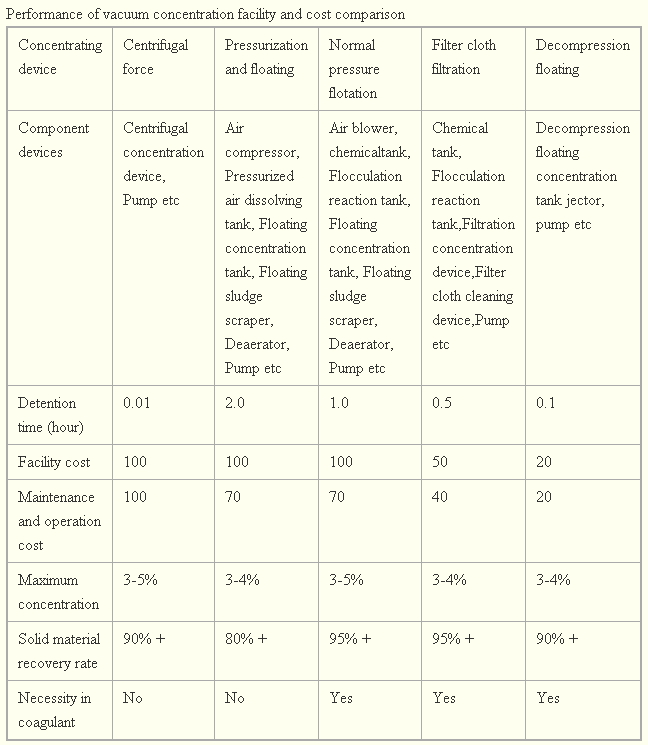

Performance of vacuum concentration facility and cost comparison

The vacuum concentration facility consists of fewer devices compared with conventional mechanical concentration facilities. In addition, our company’s facility is compact, because the sludge retention time in our company’s facility is significantly shorter than that of facilities using other floating concentration methods. Thus, the facility cost and its maintenance cost are much lower, compared with those of facilities using other methods.The sludge concentration ratio and maximum concentration of our method are comparable to those of other methods. The solid recovery rate is ensured to be 90{659260bfee9de372d251cf0f46d0d196324d619c8a7170325fda8dcf2b881e37} or more.

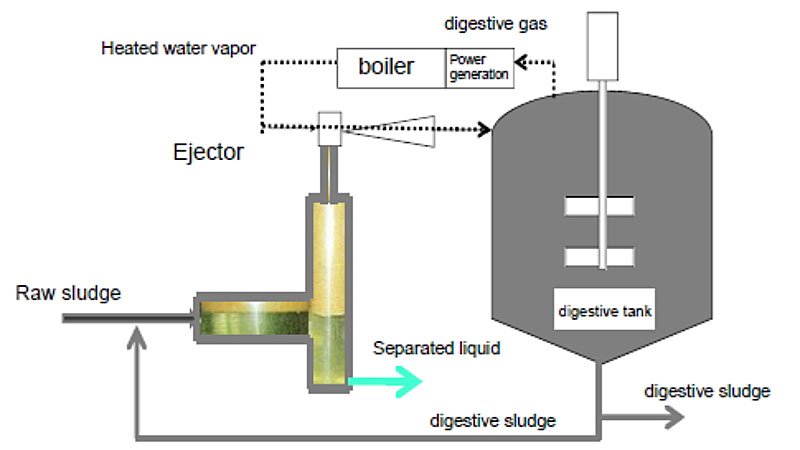

Application to methane fermentation system

While the vacuum concentration dehydration system uses a water ejector as a vacuum device, there is a method for using heated steam as a high-speed fluid for the ejector. In this case, thermal reforming of concentrated sludge is possible due to steam condensation heat and cavitation effects. By thermal reforming, sludge dehydrability is enhanced and methane fermentation is facilitated. Vacuum treatment using a heated steam ejector has the following features:

- Due to sludge concentration and thermal treatment effects, sludge is reformed and its dehydrability is enhanced.

- Due to the heated steam concentration and cavitation effects,sludge is solubilized and methane fermentation is facilitated.

- Since digestion fluid can be concentrated again to re-digest solid materials, sludge can be digested in the digestion tank using high concentration fluid.

By this sludge concentration systems, the sludge treatment and the water treatment cost can be reduced by the following features for sludge reduction.

- By reducing the moisture content of dewatered sludge, sludge disposal costs can be reduced.

- The methane fermentation system by this technology can significantly improve the digestibility and reduce sludge disposal costs.

- The pretreatment system for wastewater including solids and oil by this technology can reduce the cost of water treatment.