Ultrasonic Membrane Anaerobic System (UMAS) for Palm Oil Mill Effluent (POME) Treatment

Palm oil mill effluent (POME) is an important source of inland water pollution when released into local rivers or lakes without treatment. The production of palm oil, however, results in the generation of large quantities of polluted wastewater commonly referred as palm oil mill effluent (POME). UMAS were found to be an improvement and a successful biological treatment system that achieved high COD removal efficiency in a short period of time.

Below Table 2 summarises UMAS performance of six inflow rates all (at six steady-states), which were established at different HRTs and influent COD concentrations.

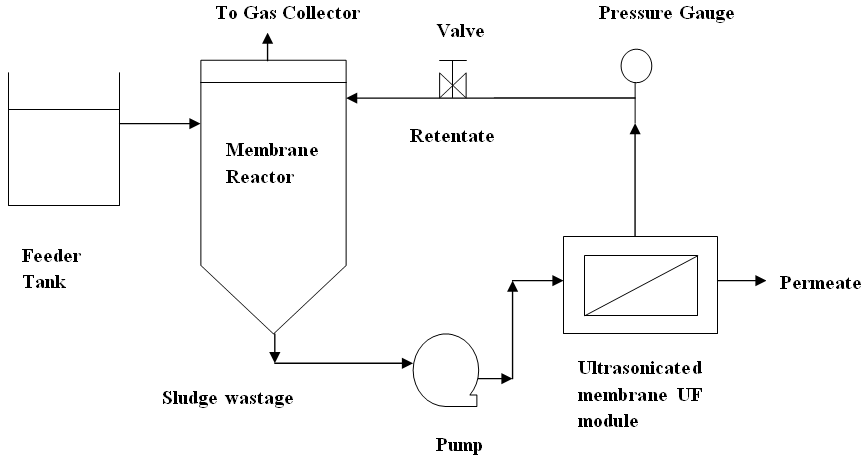

BIOREACTOR OPERATION

The ultrasonicated membrane anaerobic system, UMAS Performance was evaluated under six different inflow conditions (six steady-states) with influent COD concentrations ranging from (67,000 to 91,400 mg/l) and organic loading rates (OLR) between (0.5 and 9.5 kg COD/m3/d). In this study, the system was considered to have achieved steady state when the operating and control parameters were within ± 10{659260bfee9de372d251cf0f46d0d196324d619c8a7170325fda8dcf2b881e37} of the average value. A 20-litre water displacement bottle was used to measure the daily gas volume. The produced biogas contained only CO2 and CH4, in order to collect pure CH4, the addition of sodium hydroxide solution (NaOH) will absorb CO2 effectively and the remaining will be methane gas (CH4).

TABLE 2.

Summary of results (SS: steady state)

Full Article:

Ultrasonic Membrane Anaerobic System (UMAS) for Palm Oil Mill Effluent (POME) Treatment

Authors:

N.H. Abdurahman, and Y.M. Rosli, Faculty of Chemical and Natural Resources Engineering, University of Malaysia Pahang-UMP, Malaysia

N.H. Azhari, Faculty of Industrial Sciences and Technology, University of Malaysia Pahang-UMP, Malaysia

Reference: N.H. Abdurahman, N.H. Azhari and Y.M. Rosli (2013). Ultrasonic Membrane Anaerobic System (UMAS) for Palm Oil Mill Effluent (POME) Treatment, International Perspectives on Water Quality Management and Pollutant Control, Dr. Nigel W.T. Quinn (Ed.), ISBN: 978-953-51-0999-0, InTech, DOI: 10.5772/54459. Available from: http://www.intechopen.com/books/international-perspectives-on-water-quality-management-and-pollutant-control/ultrasonic-membrane-anaerobic-system-umas-for-palm-oil-mill-effluent-pome-treatment